Darkling beetles are persistent pests in poultry production, commonly found in broiler and turkey houses. Modern barns provide the warmth, food and moisture these insects need to thrive. Without control, beetle populations can grow rapidly—damaging buildings, disturbing birds, and reducing feed efficiency. Even more concerning, darkling beetles are mechanical vectors of disease pathogens such as salmonella, fowl pox, and botulism. These diseases can spread quickly within a house and even travel beyond it, since beetles are invasive and capable of flying up to a mile to nearby farms and residences.

Although insect control may not always seem like the top priority in poultry operations, it is vital for both animal production and staff well-being. An integrated pest management (IPM) approach is recommended, combining chemical and non-chemical methods. For beetles, litter management is essential to reduce conducive environments. Insecticides should be applied only when monitoring indicates thresholds are exceeded. Monitoring can be done with traps and by checking under feed pans—key spots for beetle activity.

Selecting and Rotating Insecticides for Long-Term Control

When insecticides are needed, manage or till litter first—unless treating windows. Applying insecticide before tilling can leave untreated gaps. For maximum residual impact, apply insecticides as close to bird placement as possible.

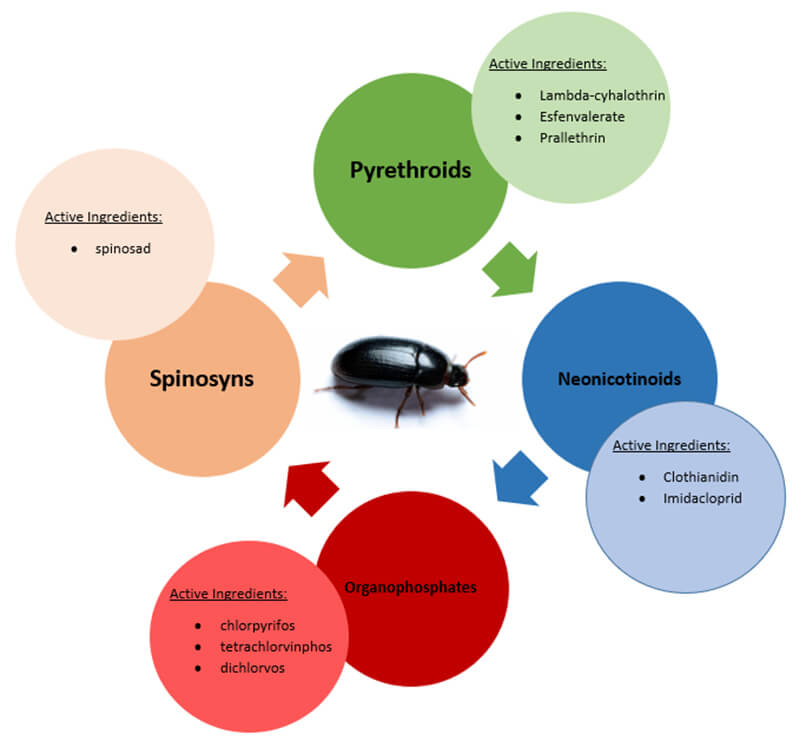

Every insecticide contains an active ingredient classified by its mode of action (MoA)—how it kills the insect. Relying too long on a single MoA risks resistance, allowing tolerant beetles to survive and reproduce. Resistance can be managed with piperonyl butoxide (PBO), a synergist that boosts insecticide performance, and by rotating insecticides across multiple classes. Ideally, switch chemical classes at least twice a year.

Microencapsulated insecticides are popular because their capsules slowly release active ingredients, extending control. For applicators seeking an all-in-one option, Tobex® Multi MoA Concentrate combines a microencapsulated residual, a knockdown agent, PBO and an insect growth regulator (IGR).

IGRs add another layer of protection by disrupting insect development, preventing immature beetles from maturing into reproductive adults. For example, NyGuard® IGR Concentrate helps reduce future beetle populations. Many applicators combine adulticides with IGRs to target all life stages, producing faster and more effective results. For best performance, apply IGRs where immature insects are most likely to be found.

Optimizing Insecticide Application

Liquid insecticides can be applied as either banded or whole-house treatments.

- Banded applications focus under feed/water lines and along walls, saving time and product but leaving untreated areas where beetles can persist.

- Whole-house applications cover all surfaces, requiring more time but leaving no untreated harborage, which reduces resistance pressure.

Avoid tank mixing litter amendments with insecticides. Acidic amendments can degrade insecticides, reducing effectiveness. Instead:

- For dry amendments: apply insecticide first, allow it to dry fully, then apply the amendment.

- For wet amendments: apply the amendment first, allow it to dry, then follow with insecticide.

Learn more about optimizing darkling beetle treatments from MGK expert J.B. Howell when he appeared on the WATT Poultry Chat.

Because darkling beetles can fly between facilities, applying residual insecticides on the exterior premises at least twice per year is recommended. Continued monitoring is essential to confirm beetle populations are declining.

Five Tips to Keep Beetles Under Control

- Pair insecticides with good litter management for full coverage.

- Rotate your insecticides regularly to avoid resistance development.

- Keep insecticide treatments and litter amendments separate.

- Adding IGRs to your program to target immatures insect stages.

- Remember to treat premises to stop beetles at entry points.

By taking a proactive, integrated approach, producers can improve long-term beetle control, protect bird health, and prevent costly infestations before they impact performance and productivity.

Need a rotation plan customized for your poultry operation? Reach out to MGK’s team—we’re here to help you get the best results!